5-Step Manufacturing Process

From design to delivery, our streamlined process ensures precision, quality, and efficiency at every stage

Design & Engineering

Our experienced engineers work closely with you to design custom wire harness solutions that meet your exact specifications.

Material Preparation

Automated wire cutting and stripping systems ensure precise dimensions and consistent quality for every component.

Assembly & Crimping

Our automated and semi-automated crimping stations deliver consistent, high-quality terminal connections.

Testing & Validation

100% electrical testing and comprehensive quality checks ensure every harness meets specifications.

Final Assembly & Packaging

Final assembly operations including overmolding, heat shrink application, and protective packaging.

Multi-Stage Quality Control System

Comprehensive quality assurance at every production stage, from incoming inspection to final testing

Incoming Inspection

All raw materials and components are inspected upon arrival to verify specifications and quality.

- Wire gauge verification

- Connector damage inspection

- Terminal spacing checks

- Material certification review

In-Process Controls

Continuous quality monitoring throughout production with statistical process control.

- Cut length verification

- Strip length measurement

- Crimp height inspection

- Pull force testing

Final Testing

100% electrical and visual inspection of finished assemblies before shipment.

- Continuity testing

- Hi-pot dielectric testing

- Resistance measurement

- Visual workmanship inspection

Advanced Technologies

AI-driven inspection and automated testing systems for enhanced quality assurance.

- AI vision inspection (96.8% accuracy)

- Real-time monitoring & analytics

- Automated optical inspection (AOI)

- Traceability systems

Certifications & Quality Standards

ISO-certified manufacturing facilities adhering to international quality and safety standards

ISO 9001:2015

Quality Management System

Company-wide quality processes and continuous improvement

IATF 16949:2016

Automotive Quality Management

Automotive industry-specific quality requirements

IPC/WHMA-A-620

Cable & Wire Harness Standards

Requirements and acceptance criteria for cable assemblies

ISO 13485:2016

Medical Device Quality System

Quality management for medical device manufacturing

UL Certification

Product Safety Standards

Electrical safety and performance compliance

RoHS & REACH

Environmental Compliance

Restriction of hazardous substances

Advanced Manufacturing Capabilities

Cutting-edge technology, global infrastructure, and expert teams delivering superior results

Advanced Equipment

State-of-the-art automated production lines and precision testing equipment

- Automated wire cutting & stripping

- Robotic assembly systems

- Laser wire marking

- Ultrasonic welding

Global Facilities

5 manufacturing facilities across 4 countries with 10,000+ SQM production space

- China (Shenzhen & Shijiazhuang)

- Philippines (Cavite)

- Thailand (Ayutthaya)

- Poland (Warsaw)

Expert Team

Experienced engineers and skilled technicians with deep industry knowledge

- 50+ design engineers

- 200+ skilled assemblers

- Industry certifications

- Multilingual support

Production Capacity

Scalable manufacturing from prototypes to high-volume production runs

- Low MOQ from 100 pieces

- High volume up to 500K/month

- 24/7 production capability

- Quick turnaround (5-15 days)

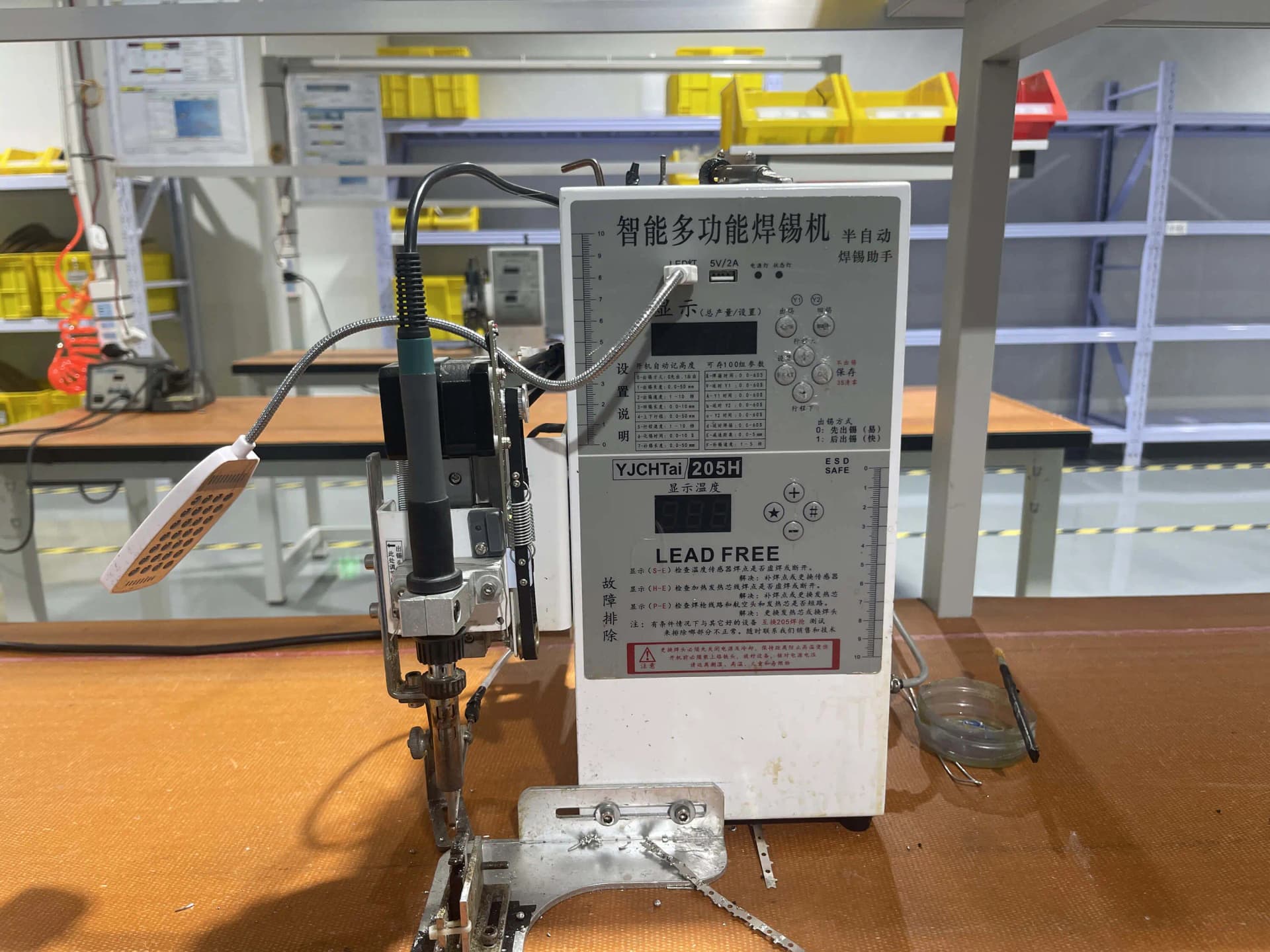

State-of-the-Art Equipment Gallery

Advanced machinery and testing equipment ensuring precision and quality in every wire harness

Fully Automatic Terminal Crimping Machine

Semi-Automatic Terminal Crimping Machine

Precision Cutting & Stripping Equipment

Vision Inspection System

Comprehensive Testing Equipment

Cable Braiding Machine

Conveyor Heat Shrink Oven

Semi-Automatic Soldering Machine

Quality Control Laboratory

Why Choose WellPCB?

Your trusted partner for high-quality wire harness manufacturing with proven excellence and reliability

8+ Years of Excellence

Since 2017, WellPCB has been delivering high-quality wire harness solutions to global customers across automotive, medical, industrial, and robotics sectors.

100% Quality Guarantee

Every single wire harness undergoes comprehensive electrical and visual testing. We stand behind our products with full quality assurance.

Multi-Brand Ecosystem

Part of OurPCB Group with 5 specialized brands (OurPCB, WellPCB, Wiringo, CloomTech, Cloom.com.cn) providing comprehensive manufacturing solutions.

Competitive Pricing

Direct factory pricing with no middlemen. Benefit from our economies of scale and efficient production processes.

Technical Support

Dedicated engineering support from design to production. We help optimize your designs for manufacturability and cost.

Fast Turnaround

Rapid prototyping (3-5 days) and production (5-15 days). Our streamlined processes ensure you get products when you need them.

End-to-End Manufacturing Workflow

Seamlessly integrated processes from initial consultation to final delivery

Inquiry

Quote

Design

Sample

Production

Testing

Delivery

Ready to Experience Our Manufacturing Excellence?

Contact our team today to discuss your wire harness requirements and discover how our advanced capabilities can benefit your project.